Bioreactor

Bioreactors are vessels that have been designed and produced to provide an effective environment for enzymes or whole cells to transform biochemicals into products. In some cases, inactivation of cells or sterilization is carried out in the bioreactor such as in water treatment. Many different bioreactors and bioreactor applications are described, including those for cell growth, enzyme production, biocatalysts, food production, milk processing, extrusion, tissue engineering, algae production, protein synthesis, and anaerobic digestion. Methods to classify bioreactors are presented, including operational conditions and the nature of the process. The emphasis is on reactors that are produced commercially rather than on reactors that have evolved in the natural world. Bioreactors used for DNA and protein synthesis (biomolecular synthesizers) are included. Commodity products include all substances that are produced in bioreactors and marketed; however, the emphasis is on general principles and more widely used bioreactor types and products.

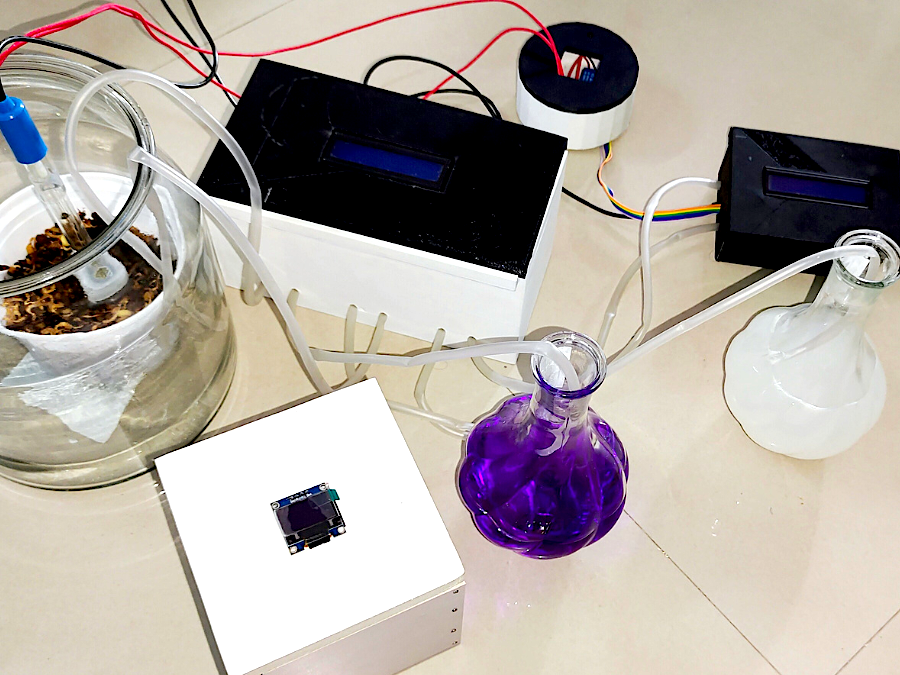

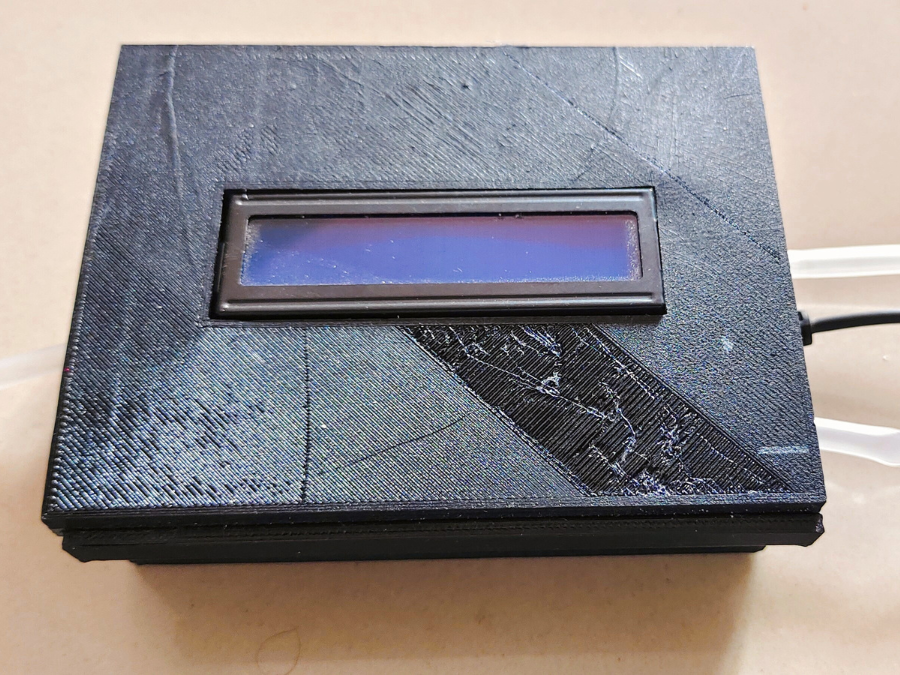

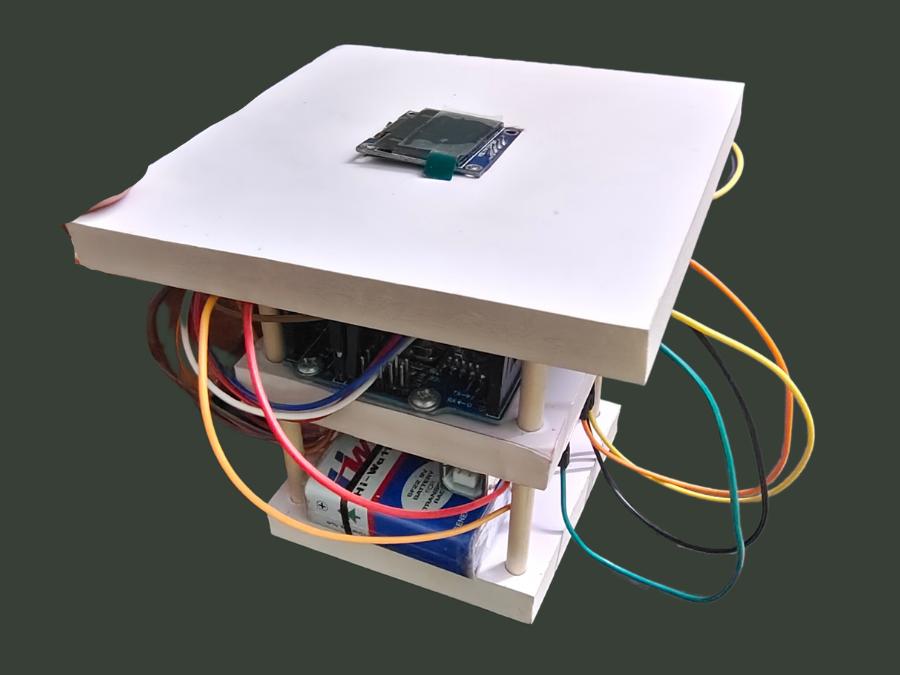

We are building an open source, tabletop, batch bioreactor to optimise yield of enzymes recombinant proteins or cells or cell tissues producing for molecular biology such as Taq polymerase or for cell-free extract production. This will build on existing open-source projects to further reduce the cost of components, ruggedness and pay particular attention to their global accessibility. By generating a modular design with thorough and useful documentation of different options to suit budget and accuracy requirements, we will make these devices easier to build and maintain for a wider range of users in universities, companies, and biomarker spaces: in particular those in resource-constrained contexts.

Apart from this to improve the analysis part and to acquire the wisdom of understanding the synthetic environmental growth in the proteins cells, we have come up with various results under certain circumstances where we grasped the parameters from certain altitude above the ground levels with the help of a pop soda tin or can sized satellite named CANSAT!

A CANSAT is a type of sounding rocket payload used to teach space technology and for research analysis parts. It is similar to the technology used in miniaturized satellites. In CANSAT competitions, the payload is required to fit inside the volume of a typical soda can (66mm diameter and 115mm height) and have a very low mass. The CANSATs are deployed from small rocket at height which varies depending on the competition. CANSATs are used to teach space technology, because of their inexpensive price and small volume.

Here in this project, we interlinked TABLETOP BIOREACTOR with CANSAT. We’ll be first launching the CANSAT and after it reaches to certain altitude (i.e., 1.2km from earth in this project. Range varies with regards to the hardware components) the telemetry data is recovered from the CANSAT and therefore directly fed to the Bioreactor. Generally, the telemetry data contains most of the required parameters to observe the growth of the cells that is PH values, temperatures, humidity, air purity etc… (at 1.2km altitude from earth). The parametrized telemetry data fed to Bioreactor from CANSAT will be received & considered by the microcontrollers therefore will be organising the addition or substitution of material accordingly to obtain the desired output for the cell growth. Results are showcased at the bioreactor through displays and for continuous uninterrupted monitoring it is also synchronized through mobile application. By this we get a clear-cut exploration and idea how the result will be when it comes to the growth of the cells with the parameters given by CANSAT.

About

Bharath Dynamics Limited

Bharat Dynamics Limited (BDL) is one of India's manufacturers of ammunitions and missile systems. It was founded in 1970 in Hyderabad, Telangana, India. BDL was established to be a manufacturing base for guided weapon systems and begun with a pool of engineers drawn from Indian Ordnance Factories, DRDO and aerospace industries, It began by producing a first generation anti-tank guided missile - the French SS11B1. This product was a culmination of a licence agreement the Government of India entered into with Aerospatiale. BDL has three manufacturing units, located at Kanchan Bagh, Hyderabad, Telangana; Bhanur, Medak district, Telangana and Visakhapatnam, Andhra Pradesh.Two new units are planned at Ibrahimpatnam, Ranga Reddy district, Telangana and Amravati, Maharashtra.

Lovely Professional University

Lovely Professional University (LPU) is a private state university located in Chaheru, Phagwara, Punjab, India. The university was established in 2005 by Lovely International Trust, under The Lovely Professional University Act, 2005 (Punjab Act 25 of 2005) and started operation in 2006. The university has 45+ teaching and research departments at the campus located at Chaheru, Phagwara, Punjab and more than 360+ Programme in various undergraduate, post-graduate and doctorate degrees in various disciplines including engineering, agricultural science, legal studies, management, computer sciences, education, media studies, animation and multimedia, tourism, biotechnology, architecture, pharma sciences, commerce, liberal arts and basic sciences.

Guide

K SUNIL PHANI

MANAGER, ITD CELL

BHARATH DYNAMICS LIMITED

BHANUR UNIT

Contact details:

Mobile : +91 9490123821

Telephone : 040-23469574

Team members

SARIPALLI HARI HARA BABU

B.TECH

ELECTRICAL AND ELECTRONICS ENGINEERING

LOVELY PROFESSIONAL UNIVERSITY

PHAGWARA, PUNJAB

Email : harihara13121995@gmail.com

DEVATH AKHILA

B.TECH

ELECTRICAL AND ELECTRONICS ENGINEERING

LOVELY PROFESSIONAL UNIVERSITY

PHAGWARA, PUNJAB

Email : devathakhila59@gmail.com